Popular Science Topic

Popular Science Topic

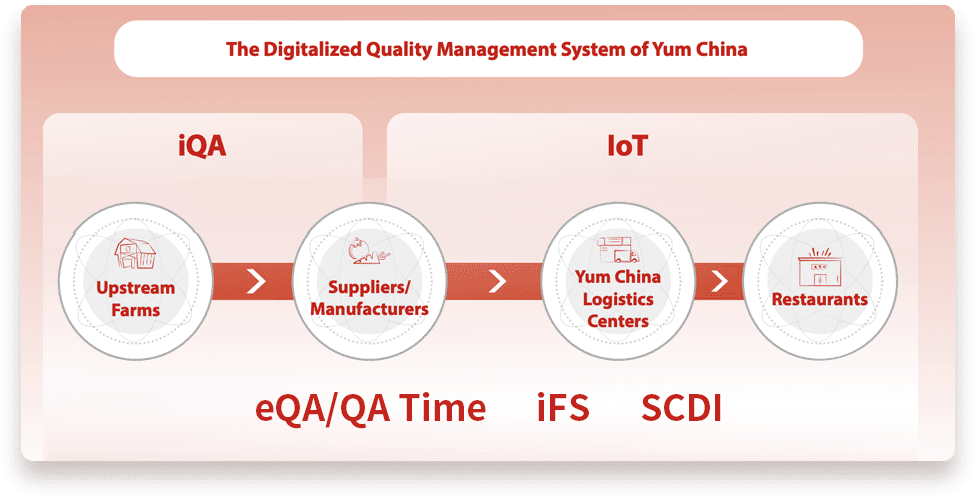

Food safety is our top priority at Yum China. We have made a substantial investment to build an industry-leading, intelligent, digitalized food safety and quality management system. Utilizing Artificial Intelligence (AI), Internet of Things (IoT), and real-time data collection and analysis, we have established rigorous control measures across the value chain.

Yum China Holdings, Inc.

- Food safety and quality audit covers 100% of restaurants and logistics centers

- Food safety and quality training covers 100% of employees in offices, restaurants, and logistics centers

- Food safety assessment covers 100% of food and food contact packaging suppliers

Food safety is

our top priority.

We are dedicated to building an advanced food safety system and strive to provide customers with safe food.

We believe in shouldering additional social responsibilities and setting an example in the industry.

To ensure the development and effective implementation of food safety management processes and standards, Yum China has established a holistic, top-down food safety management mechanism that spans from the Board of Directors/Food Safety and Sustainability Committee to functional management teams. This governance system provides comprehensive oversight and effective execution of various management systems, measures, and standards to ensure food safety and compliance.

and Sustainability Committee

- The Board maintains overall responsibility for overseeing the Company's risk management framework.

- The Food Safety and Sustainability Committee assists the Board in its oversight of the Company's practices, policies, procedures, strategies and initiatives relating to food safety and sustainability.

Management Team

- Compliance Oversight Committee:

- The committee is comprised of leaders from various functions, such as Legal, Internal Audit, Supply Chain Management, Public Affairs, Information Technology, Finance, and Human Resources

- The committee meets regularly to assess risks, monitor internal controls, and determine strategy and approach to promote compliance

Management Team

- Supply Chain Risk Assessment Meetings:

- Food Safety, Quality, and Nutrition Regulation (FSQNR) Team, Procurement Management, and when necessary, involve other functions

- Assess risk in areas such as suppliers, logistics centers, and restaurants and formulate preventive measures

- Conduct food safety audits on suppliers, logistics centers, and restaurants

Operations Teams

- Restaurant manager on-duty inspections

- District manager patrol inspections

Yum China Audit Teams

- Food safety/quality audit

External experts from various fields are invited to share best

practices to drive continuous improvement of

Yum China's food safety management processes

We believe every Yum China employee has the responsibility to understand and embrace the Company's food safety values.

For office and restaurant employees, we require every new employee to learn and sign the Yum China Code of Conduct Confirmation Letter or Employee Manual Confirmation Letter. We provide all our employees with access to online food safety courses that enable them to understand food safety laws, regulations, and Yum China's standards. We mandate that restaurant employees receive rigorous job training to ensure they understand and implement the Company's food safety standards with the utmost care.

In addition, we require and guide our franchisees to establish a food safety culture. All franchisees must sign the Franchise Policy Manual, which binds them to adhere to Yum China's Operations Manual, Code of Conduct, and safety and hygiene standards. Furthermore, they must undergo annual food safety training to reinforce their knowledge of national food safety laws and regulations, Yum China's food safety policies, and industry trending topics.

Upstream Suppliers

Upstream Suppliers

Suppliers

Suppliers

Logistics

Logistics

Restaurants

Restaurants and Delivery

Yum China mandates that suppliers establish procedures for

approving and monitoring upstream suppliers to effectively

identify and manage potential food safety risks associated

with their raw materials.

As poultry is a significant

ingredient in our food, we focus on managing the source and

invest considerable resources in establishing a

comprehensive control system for the broiler industry,

spanning from breeding to slaughtering and to meat

processing. We have implemented an electronic farm

information system to register and monitor the usage of

veterinary drugs on Yum China-approved poultry farms. Using

this system, we conduct unannounced farm inspections and raw

material food safety monitoring tests to assess upstream

suppliers' performance and reinforce traceability.

Furthermore, we collaborate with our suppliers, promoting

the implementation of Yum China GAP, requiring farmers and

producers to take scientific, prudent, and responsible

approaches. Our partners are required to implement

systematic control measures from farm selection, soil and

water safety, pesticide management, and fertilizer

application, to the implementation of good manufacturing

practices, thereby effectively preventing the occurrence of

food safety issues.

Our Yum China GAP has achieved 100% coverage in lettuce,

tomato and pepper*, oranges, lemons, apples, and broccoli

bases. In 2023, we started to cover sweet corn, and continued

to expand to other category bases.

*Tomato and pepper bases produce mainly tomatoes, cherry

tomatoes, green peppers, cayenne peppers, and cucumbers.

Supplier Approval

Yum China has established a rigorous supplier admission mechanism that encompasses risk assessment,

qualification review, and factory audit. In addition, we require all new suppliers to complete training

on the Yum China Quality Management Institute e-learning platform on our audit standards and pass the

required assessments before entering our admission process.

Supplier Management

Standards: We continue to advance the development of suppliers' food safety systems and capabilities, recognizing food safety certifications endorsed by the Global Food Safety Initiative (GFSI), such as BRCGS and FSSC 22000, which are considered equivalent recognition by Yum China's food safety audits.

Training: We held annual STAR training for all food suppliers to keep them up to date about Yum China's latest requirements on food quality.

Audits: We carry out STAR audits to verify whether the suppliers' food safety and quality management systems meet our requirements.

Sampling Tests: Yum China develops an annual raw material food safety sampling plan and conducts random tests to ensure compliance with relevant standards.

Performance Evaluation: Yum China has established a comprehensive supplier performance evaluation system that assesses food safety and quality performance quarterly. Based on the evaluation results, we graded the suppliers, formulate targeted improvement measures, and promote supplier optimization and improvement.

In 2024: Over 80% of our food ingredient and food-contact packaging suppliers obtained GFSI-benchmarked food safety certifications. Yum China conducted more than 300 food safety and quality audits on supplier and over 3,300 sampling tests for raw material food safety and quality.

Yum China operates a tailor-made, world-class logistics management system to secure food safety and provide efficient and

reliable logistics services for our restaurants. We also conduct regular audits and routine inspections on our logistics

service providers (including warehouse, transportation, and unloading of goods) to verify that their food safety and quality

management systems meet our requirements.

Furthermore, we utilize the latest technologies to monitor the food safety of cold chain logistics and warehousing processes.

We have implemented a smart IoT platform to monitor the movement of food ingredients from suppliers to logistics centers and

then to restaurants. This platform also tracks the real-time temperature of vehicles, cold storages, and refrigerated warehouses,

as well as the products' temperature from logistics centers to the restaurants, enabling us to promptly identify potential food

safety risks. We continue to invest in the supply chain infrastructure to widen our strategic moat and strengthen business

flexibility and resilience. This allows us to maintain high synergy and sustainability in special circumstances, reducing

the adverse effects of supply disruptions such as the COVID-19 pandemic. Through cooperation with suppliers, as well as a

vast logistics network, we can continuously supply all food products without significant interruption.

By the end of 2024, our network comprised utilized 33 logistics centers to which distribute goods to our company-owned stores

and franchise stores.In 2024, we conducted over 170 food safety and quality audits with warehousing and transportation service providers.

Audits and Inspections:

FSQNR Team conducts regular unannounced Operational Excellence Compliance (OEC) Audits on all restaurants, covering food safety,

product quality, and customer service to ensure full compliance with established food quality and safety standards at every stage

before the food is served to our customers. We also conduct regular quality assessments of microbiological sampling and testing of

food utensils, tableware, water, ice, and related products to help ensure compliance.

Restaurant Operations Management:

Yum China has established industry-leading restaurant operating standards and procedures covering raw material receiving, storage,

thawing and cooking, shelf-life management, personal hygiene, and utensil and equipment cleaning and disinfection. These help ensure

that all our restaurants implement consistent food safety standards and provide food with consistent quality and taste. We conduct

annual risk assessments at our restaurants to identify potential food safety and quality risks and take effective measures to mitigate

risks and eliminate hazards. We also conduct risk assessments for new products, new restaurant layouts, equipment, and store operations

to help ensure compliance with food safety and quality requirements.

Delivery Management:

We have established industry-leading operation standards and protocols, requiring all third-party delivery partners to sign and strictly

adhere to a letter of commitment on the food safety and quality practices for food delivery. The letter outlines specific requirements

for regulatory compliance, staff management, catering, delivery facilities, equipment as well as rigorous management of third-party

platforms, to ensure the implementation of food safety operation procedures.

In 2024, OEC audit coverage for restaurants nationwide was 100%. We conducted over 10,000 product quality assessments for about 600 new or upgraded menu items.

Trending Issues

Trending Issues

Yum China's robust digital capabilities are unlocking new possibilities for

comprehensive food quality and safety management across the entire value chain.

We are actively exploring the extensive application of advanced digital and

intelligent technologies to build an industry-leading digital supply chain,

driving transformation in food safety governance.

1. Precise and Timely Food Safety Risk Prevention and Control

Leveraging over 30 years of expertise in food safety and quality management,

Yum China has developed an interconnected food safety big data ecosystem. Since 2020,

we have deployed a Food Safety Risk Assessment and Early Warning Management System

that utilizes cutting-edge machine learning and deep learning technologies and

algorithms such as knowledge graph and natural language processing (NLP).

Through four years of continuous research and development, and iterative upgrades,

the system now integrates eight functional modules, such as risk warning and risk assessment,

with sustained performance optimization across all modules.

2. Strict Food Traceability and In-Transit Supervision

We continuously implement our IoT Cold Chain Monitoring System to ensure effective

food safety management throughout our logistics operations. During the reporting period,

we extended the practice to include real-time monitoring of inbound logistics transportation

managed by raw material suppliers. We are also actively exploring the substitution and

assistance of Artificial Intelligence-Generated Content (AIGC) in manual monitoring processes.

These advancements are enabling efficient supply chain management, enhanced food traceability

and improved in-transit supervision.

Learn More

Learn More