We have made significant investment towards building an industry

leading intelligent and digitalized supply chain. The use of

cutting-edge technologies has allowed us to combine traditional

control measures such as sampling audit, post audit rectification,

performance assessments with technology enable real-time data

collection and analysis, key processes visibility and deviation

rectification to improve efficiencies and timeliness of Yum

China's food safety management.

We harness the latest technology to continually enhance

our ability to prevent and control food safety risks. Our

Food Safety and Quality Management Platform (eQA),

connects supplier factory data with Yum China's internal

systems through the Quality Data Platform (iQA) system,

ensuring real-time food quality data monitoring. Furthermore,

our Cold Chain IoT system allows live-monitoring of storage

temperatures. We also analyze internal and external food

safety big data through our Food Safety Risk Assessment

and Early Warning System (iFS), enabling us to proactively

assess and take action to mitigate potential risks. We are

exploring the use of AI-generated content (AIGC) to

enhance our multidimensional food safety monitoring and

risk assurance.

In 2020, we codified Yum China's more than 30 years of food safety and quality management experience, and integrated internal and external food safety big data to create the iFS. iFS is a scientific and machine learning based artificial intelligent tool that can significantly improve our ability to identify and classify potential risks. This system uses technologies and algorithms including Knowledge Graph, natural language processing, and named entity recognition. The system includes 8 functional modules, with unique capabilities in risk alert and assessments. As an illustration, 2 of the key functional modules are:

Risk Alert: This module monitors data including government tests, administrative penalties, media exposure, animal pandemics, and changes of laws and regulations on a daily basis. It then classifies relevant data by category, level of impact, and cross-reference to our supply chain data to identify potential risk.

Risk assessments: This module is used in four areas, namely: new suppliers, new products, new / existing suppliers with new products, and existing suppliers with existing products. It evaluates risks holistically and generates risk assessment reports within seconds with visualizations of risk and related information.

Yum China's eQA enables online management of the entire process from farm to fork, which covers management of food safety and quality for upstream suppliers, suppliers, logistics centers, and restaurants on an integrated system. eQA is also capable of automatic verification of regulatory compliance for food additives used in raw materials for new products. As a data integration platform for food safety and quality management, it significantly improves our ability and efficiency to manage suppliers and their products

iQA is a key element of Yum China's vision of building an intelligent end-to-end supply chain that links key production data from suppliers' plant to Yum China's system. It divides the production process into seven data modules, defines control points within each module, and key data are transmitted to the system in real time during production cycle. In doing so, we realize our goal of data interconnectivity and visibility, intelligent real-time data collection, timely deviation rectification and efficient traceability of raw material in the value chain.

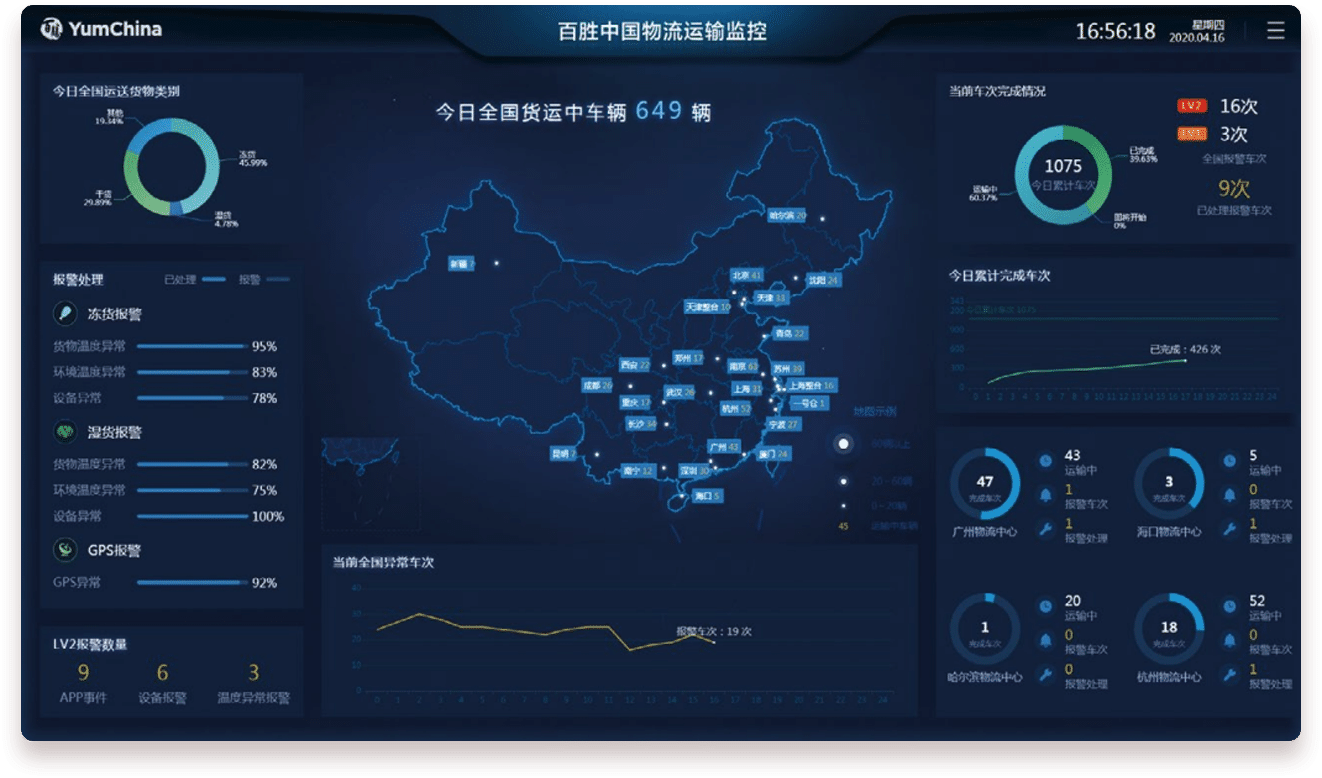

Real-time product temperature monitor-ing in the logistics cold chain is crucial to guarantee cold chain integrity and to reduce energy consumption, which has been a persistent challenge for the industry.

Yum China logistics has built a complete cold chain temperature monitoring system, relying on IoT, big data, cloud computing, and other cutting-edge technologies. From real-time tempera-ture monitoring in warehouses and compressors to real-time temperature onitoring of products in transit and vehicle conditions, our 7x24hr round the clock digitalized cold chain management system is actively using technology to safeguard food safety.

Connecting upstream and downstream supply chain data,improving risk prediction and perception capabilities through visualized management of key indicators